Bevel-X Plasma System Series

Bevel-X Plasma

Cut beveled parts with speed and precision using our industrial-quality torch beveling system. Originally engineered for 3D structural cutting, this unique design can handle the most complex of your plate beveling needs.

- Rotation axis over 180 degrees for structural cutting

- Tilt axis 52 degrees to -52 degrees

- Near zero backlash for long end effector

- Ceramic coating extremely resistant to chemicals and corrsion

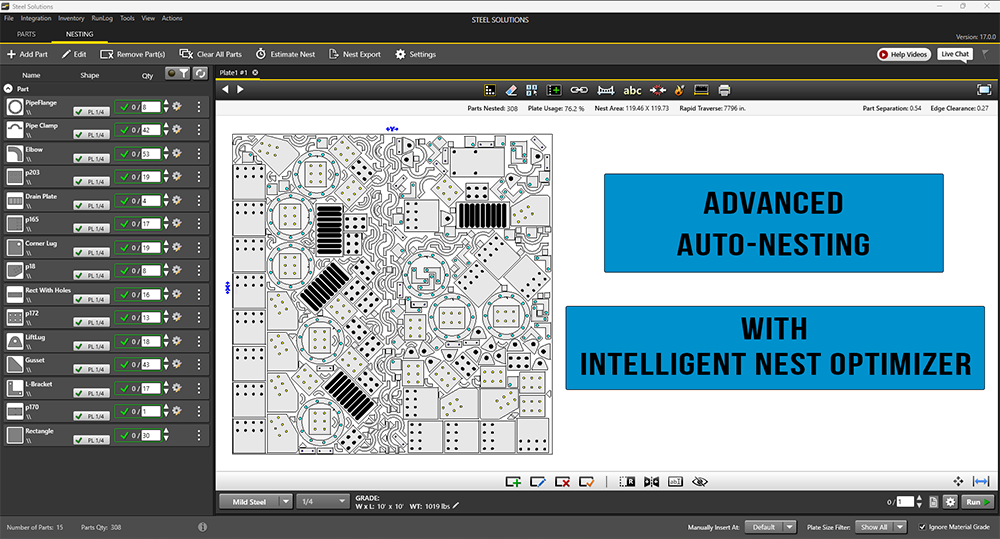

Steel Solutions® Nesting Software

With included Steel Solutions® Nesting Software, unlock your potential with a simple, clean, easy to use, but but powerful user interface.

- Advanced Auto-Nest Optimizer

- Full CAD Package (Part Creation/Editing)

- Dynamic Stencils and Heat Number Generation

- Tekla Powerfab Integration

- Load Inventory & Part Files from CSV/Excel

Nesting Software Features

Advanced Machine System Software

With the inclusion of the Nexus® Machine Software, we offer cutting-edge performance for precise and reliable machine control, built for industrial environments. Powered by a robust Industrial PC with Windows IoT and Ethercat control running on virtual Linux, it utilizes separate processor cores to deliver exceptional multitasking capabilities.

Insight® Machine Controller

Featuring an industrial-grade solid-state HD and extended wireless Ethernet, this controller ensures seamless communication and long-lasting durability.

- Automatic Plate-Skewing

- Advanced Measuring Laser

- Diagnostics with THC Graphing

- Preventative Maintenance Alerts

- Real-time 3D Interface With Interactive Part View

- Jump to Part Processing

- Clean and Easy to Use Interface

- Remnant Tracing

- Consumable Life Tracking

- Saved Locations / Home Points

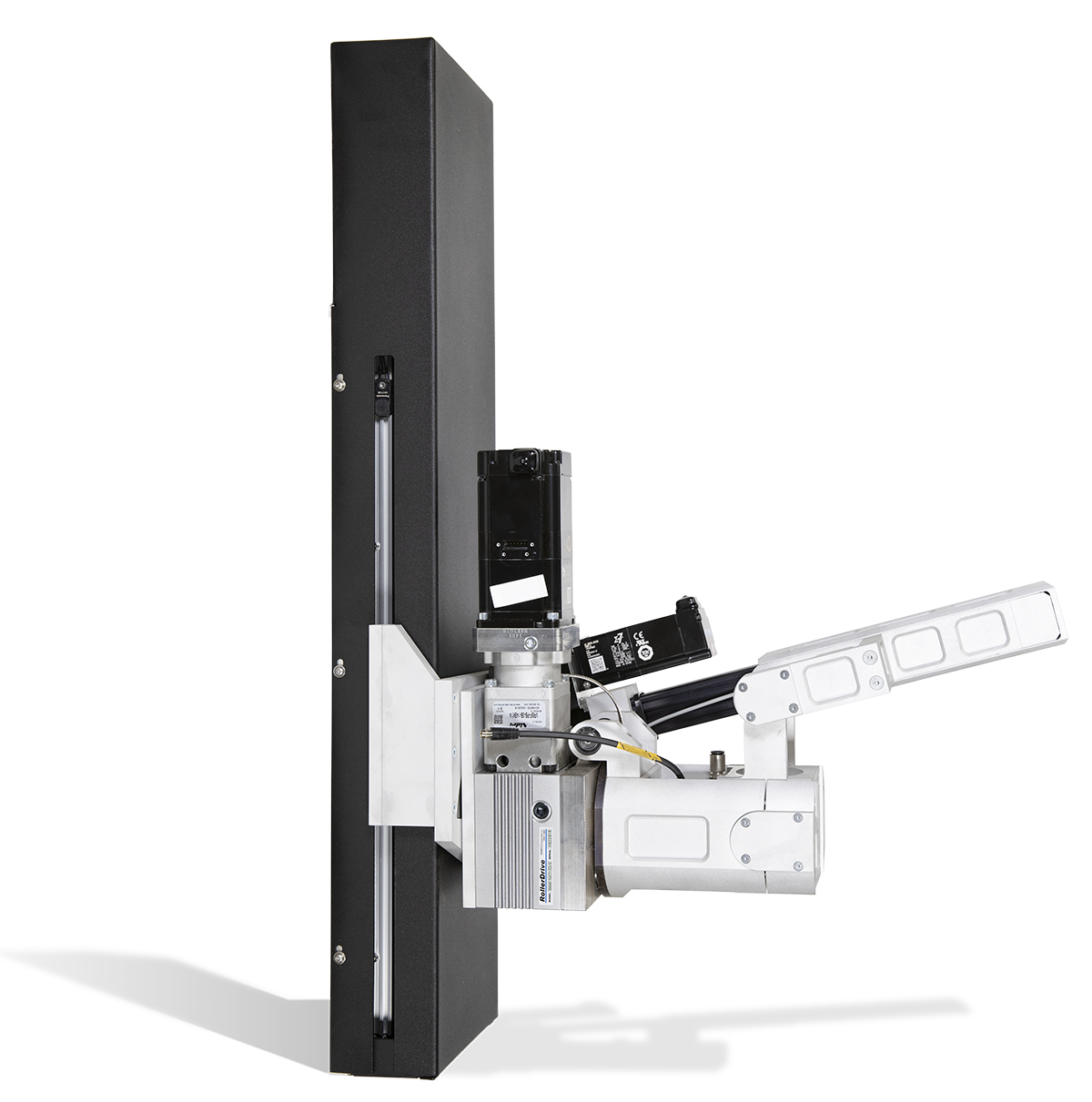

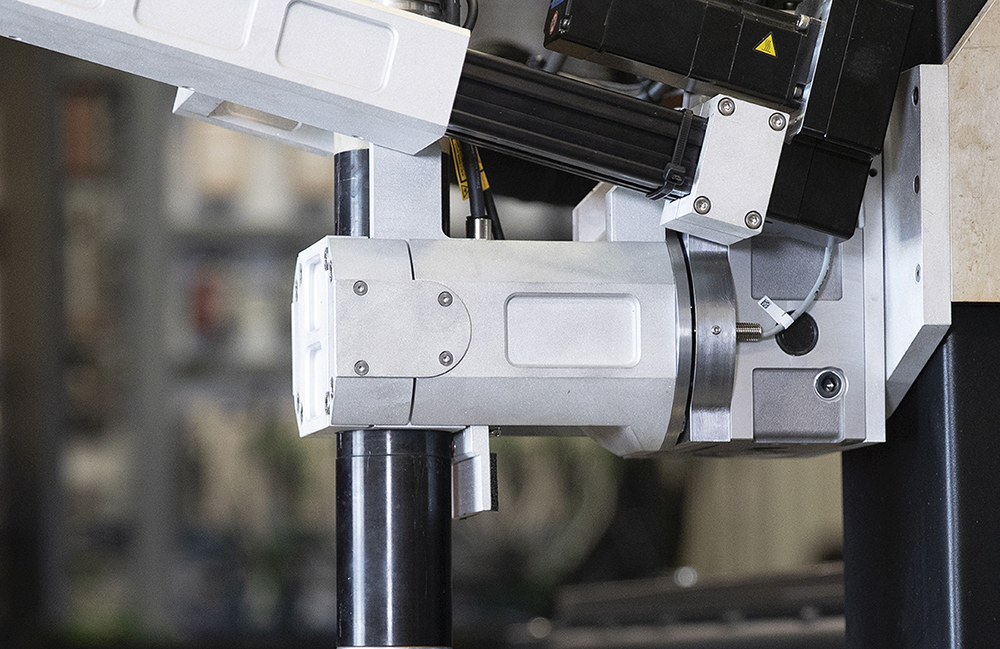

5-Axis Torch Beveling

Our compact 5-axis plate beveling unit gives the plasma torch a full 360 degree range of motion. When designing this system, our goal was to build an industrial quality bevel-head that would expand beyond the capabilites that are typically offered on a plate cutting machine.

Consistent Quality Results.

Our high performance bevel-head with auto-calibration ensures high quality parts time and time again. When combining our advanced beveling system with the new drill, the possibilities are pushed far beyond those of a standard plate cutting machine.

Robust Bevel Lifter

Designed for the high-speed and precise movements that are required for beveling applications, our robust bevel lifter takes height control to another level. This lifter is built to handle the tough demands of production bevel cutting.

- Bearing design and preload for beveling application

- Gravity compensation pnematic counterbalance

- High speed to get that torch to the next orientation

Industrial Grade Design

From decades of experience in automation, we have learned the value of simplicity to keep the customer downtime to a minimum. Lightweight, protected from harsh enviroments and easy to service, our beveling system is built with longevity and reliability in mind.

Saved Locations

If you have specific locations on your machine that are frequently used for tasks like changing consumables, torch maintenance, loading/unloading plates/parts, this feature of saving these locations is a great time saving tool, eliminating the need to manually jog to these spots over and over again.

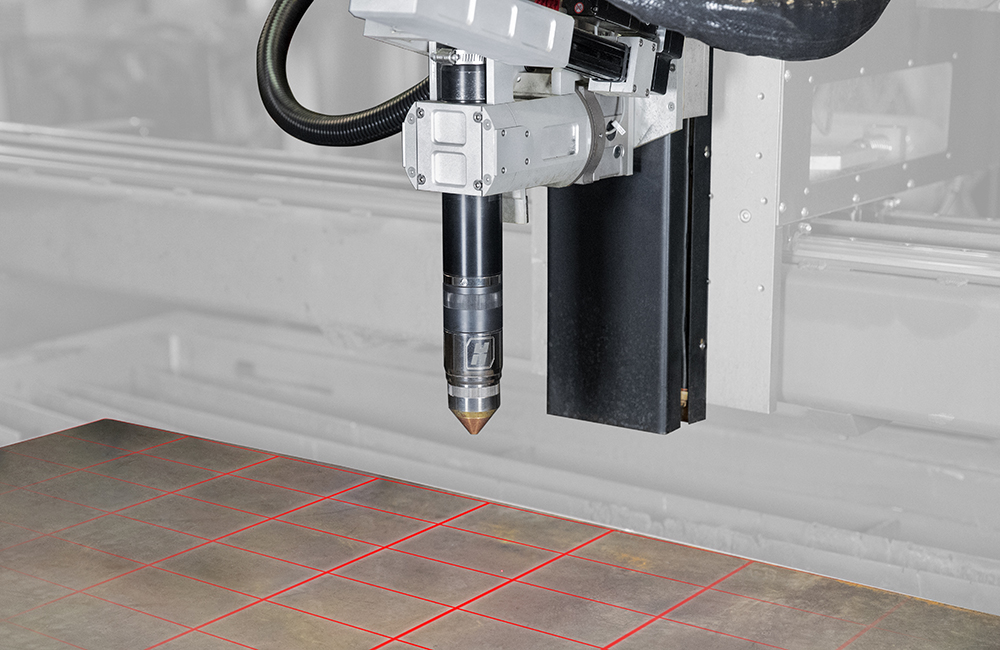

Advanced Plate Mapping

Manufacturers have dealt with the unreliable technique of voltage height control for years. With our laser mapping system for bevel cutting, you can get reliable and repeatable bevel cuts every time.

Pipe & Dome Cutting Upgrades

If you have the need to process and perform advanced miters, saddle-cuts, beveled holes and more, we have you covered. From start to finish, our upgrade packages for the Insight Machine Controller and Steel Solutions nesting software have full CAD/CAM pipe and dome creation and editing, and quality cuts time and time again.

Upgrade Your System

With the available Pipe & Dome Cutting upgrades to your Insight® controller and Steel Solutions® nesting software, you will take your production to the next level.

- Basic & Advanced Pipe Processing

- Advanced Dome Processing

- Laser Mapping & Center Locating

- Miters, Saddle Cuts, Beveled Holes, Weld Prep, etc.

- Create & Edit Dome and Pipe in Full CAD Suite

- Rotary & Non-Rotary Beveled Cuts

Plasma Options

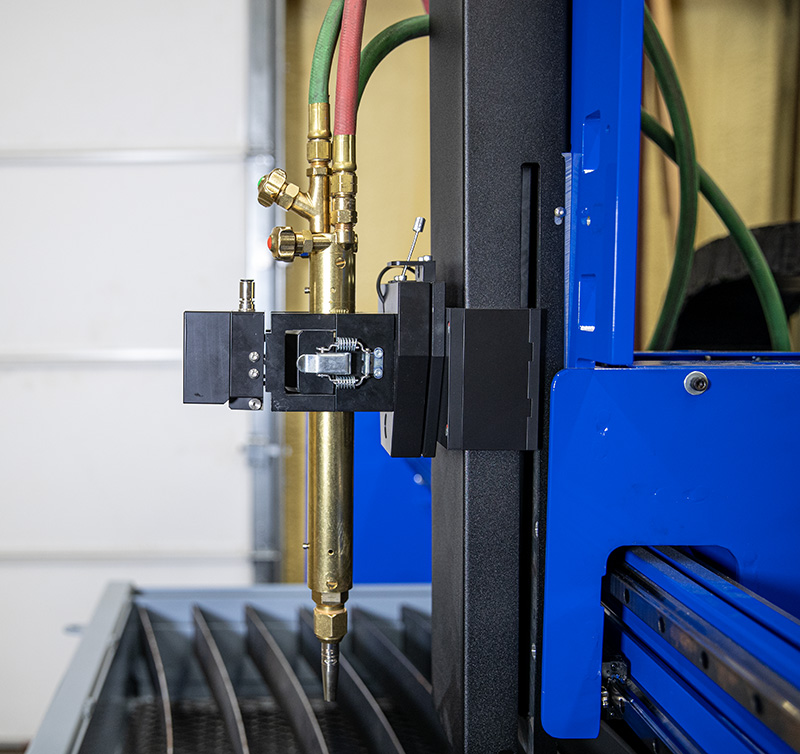

Crash Detection System

One of the unique features of this revolutionary design, the entire assembly is protected by a magnetic-mounted crash detection system. This system ensures operator safety and protection of the torch and it's consumables.

Oxy Torch Compatible

The Bevel-X system is compatible with Oxy-Fuel setups. Capable of straight cut, straight-line bevel, or full contour bevel using an interchangle torch design with an adapter for the bevel unit.

Want the very best in servo motion? Yaskawa's new Sigma 7 servo system is pushing motion to a whole new level. Sigma-7 is engineered to bring new responsiveness, reliability and effectiveness to the automation that powers your productivity. The Sigma-7 family of rotary, direct drive and linear servo products continue the legacy of the Sigma series, which has set the standard in innovation and reliability for a quarter century.

- Smooth and Precise Allowing for High Quality Parts

- Reliable and Durable to Give Consistant Results

- New Sigma-7 Servo Package Offers Next-Level Motion

- Vibration suppression,anti-resonance compensation

- Friction model compensation and ripple compensation